For radiotherapy treatment of localized cancers, telecobalt units are known for low-cost, simplicity, predictive nature of the radiation dose and low maintenance/ downtime. However, radiation field openings for any telecobalt unit are limited to rectangular fields only, even though tumor boundaries are highly irregular. As a remedy, BARC has developed the technology for Multi Leaf Collimator (MLC) System to provide complex and irregular radiation fields required for better conformity to irregular tumor geometries. The performance has been demonstrated after integrating this MLC (as secondary collimator) with our indigenous telecobalt machine.

Entrepreneurs having following experience only can apply:

Radiation therapy is used for the management of localized cancers. Telecobalt units are preferred due to low cost, simplicity, predictive nature of the radiation dose and low maintenance/downtime. As of now, the radiation field openings defined by any telecobalt unit, are limited to rectangular fields only. Multi Leaf Collimator (MLC) System can provide complex and irregular radiation fields required for far better conformity to irregular tumour boundaries, leading to superior clinical performances.

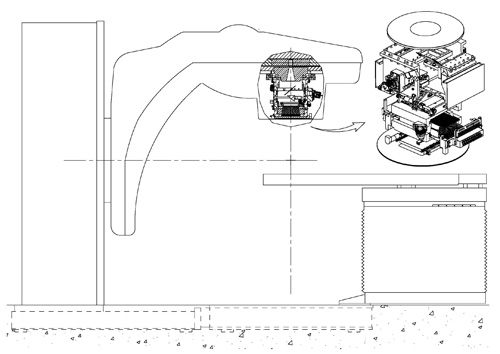

BARC has developed MLC system which serves as secondary collimator. Here, thin divergent leaves made of tungsten alloys with tongue and groove arrangement are grouped in two banks. Each of these leaves projects one centimeter at patient plane and driven independently by individual electric motor. The system has been demonstrated after integrating with our indigenous telecobalt machine with source to axis distance at 80cm. Features like collimator rotation, motorized wedge filter, field light arrangement, optical distance indicator etc are arranged without compromising the patient clearance. This new version has been approved by AERB for clinical applications. Irregular radiation fields now can be generated conforming to the complex tumour geometries, allowing higher tumour dose while limiting unwanted dose to surrounding healthy tissues resulting in superior treatment outcome.

Indigenous telecobalt units can be upgraded with this MLC by replacing the existing collimator systems. However, the design modifications in mechanical, electronics, control and software essential for integration of this MLC design with the indigenous telecobalt machine is the responsibility of the manufacturers of the teletherapy machine.

SPECIFICATIONS

| Sr. No. | Specification | Value |

|---|---|---|

| 1 | Source to axis distance (SAD) | 800 mm |

| 2 | Source to Diaphragm Distance (SDD) | 465 mm |

| 3 | Leaf Design | Divergent, with tongue and groove |

| 4 | Collimator Type | Secondary |

| 5 | Collimator Rotation | motorized, ±90 deg |

| 6 | Max. Field Size (at isocentre) | 250 mm x 250 mm |

| 7 | Min. Field Size | 0 x 0 (completely closed) |

| 8 | Leaf Projection at isocentre | 10 mm |

| 9 | Collimator Auto Set-up | Yes |

| 10 | Back-up Jaws | Yes, both axes |

| 11 | Motorized Wedge Filter | Yes (upto 60deg.) |

| 12 | Regulatory Approval | Atomic Energy Regulatory Board, INDIA |

The job involves high precision fabrication, assembly, extensive QA testing as per AERB requirements. For those having facilities for manufacturing Teletherapy machines, additional infrastructure requirement will be insignificant Manufacturing processes involved:

Machine Tools/ Equipments needed for Manufacture

Space Required

Electricity Supply

MANPOWER