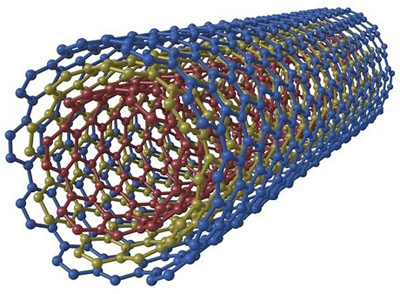

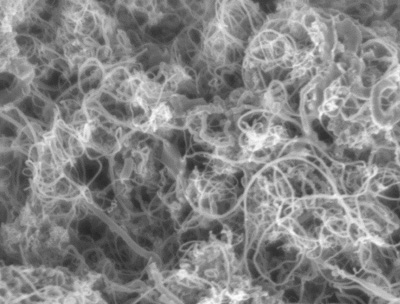

Carbon nanotube (CNT) is a one-dimensional concentric tubular structure with hexagonal arrangement of carbon atoms. It is in the form of fine powder, multi walled with 20-50nm diameter, length is 5-10µm (approx) & purity - 95%. It is well known for a combination of special material properties like very high thermal & electrical conductivities, high tensile strength, high modulus of elasticity, low density, high porosity, chemical stabilities, and high aspect ratio. Great potential in nano technology, nanomechanics, biotechnology, advanced electronics & other field of research in materials for sustainable future, green technologies including material for development of high strength composites, energy storage & energy conversion devices, EMI shielding, supercapacitor, battery electrodes, green catalysis, highly porous membrane, water purification, efficient drug delivery & biosensors, transparent conducting films, field emission display, thermal interface, electrical interconnect application.

Carbon nanotube (CNT) is a one-dimensional concentric tubular structure with hexagonal arrangement of carbon atoms. It is well known for a combination of special material properties like very high thermal & electrical conductivities, high tensile strength, high modulus of elasticity, low density, high porosity, chemical stabilities, and high aspect ratio. Great potential in nano technology, nanomechanics, biotechnology, advanced electronics & other field of material science and technology many.

Highly demanded for its application and research in materials for sustainable future & green technologies including material for development of high strength composites, energy storage & energy conversion devices, EMI shielding, supercapacitor, battery electrodes, green catalysis, highly porous membrane, water purification, efficient drug delivery & biosensors, transparent conducting films, field emission display, thermal interface, electrical interconnect application.

| Sr. No. | Specification | Value |

|---|---|---|

| 1 | Form | fine powder |

| 2 | Type | Multi walled |

| 3 | Diameter | 20-50nm |

| 4 | Length | 5-10µm (approx) |

| 5 | Purity | 95% |

Carbon nanotube (CNT) is a one-dimensional concentric tubular structure with hexagonal arrangement of carbon atoms. It is well known for a combination of special material properties like very high thermal & electrical conductivities, high tensile strength, high modulus of elasticity, low density, high porosity, chemical stabilities, and high aspect ratio. Great potential in nano technology, nanomechanics, biotechnology, advanced electronics & other field of material science and technology many.

Highly demanded for its application and research in materials for sustainable future & green technologies including material for development of high strength composites, energy storage & energy conversion devices, EMI shielding, supercapacitor, battery electrodes, green catalysis, highly porous membrane, water purification, efficient drug delivery & biosensors, transparent conducting films, field emission display, thermal interface, electrical interconnect application.

SPECIFICATIONS

| Sr. No. | Specification | Value |

|---|---|---|

| 1 | Form | fine powder |

| 2 | Type | Multi walled |

| 3 | Diameter | 20-50nm |

| 4 | Length | 5-10µm (approx) |

| 5 | Purity | 95% |

RAW MATERIALS

INFRASTRUCTURE

MANPOWER