Molybdenum metal-based alloy TZM (Mo–0.5Ti–0.1Zr–0.02C) is a potential material for high temperature applications such as nuclear reactor, hypersonic vehicle, space etc, as it offers high strength and creep properties at higher temperatures (~1500ºC). Mo in the TZM alloy forms volatile oxide vapor MoO3 at higher temperatures (beyond 700˚C) in oxidizing environments, which leads to damage of components during application. Development of a suitable protective coating is necessary for its use at high temperatures. This technology demonstrates the formation of silicide-based coating on TZM material using pack cementation technique.

Molybdenum metal-based alloy TZM (Mo–0.5Ti–0.1Zr–0.02C) is a potential material for high temperature applications such as nuclear reactor, hypersonic vehicle, space etc, as it offers high strength and creep properties at higher temperatures (~1500ºC). Mo in the TZM alloy forms volatile oxide vapor MoO3 at higher temperatures (beyond 700˚C) in oxidizing environments, which leads to damage of components during application. Development of a suitable protective coating is necessary for its use at high temperatures. This technology demonstrates the formation of silicide-based coating on TZM material using pack cementation technique.

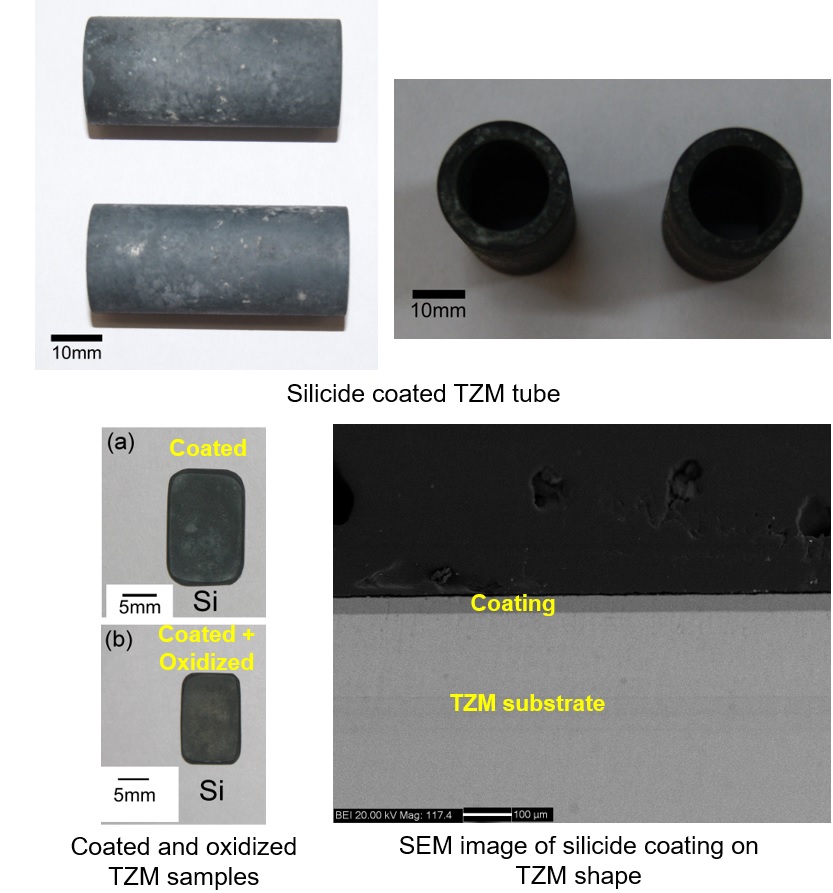

Pack siliconizing technique produces uniform and adherent coating of desired thicknesses on larger components, as well as complex geometries. The different process steps can be conducted using minimum manpower.

Formation of protective coating is necessary to improve the high temperature oxidation resistance of the TZM alloy. Silicide-based coating (MoSi2) on TZM alloy shapes is promising material against oxidation at temperatures beyond 1200º due to the formation a protective, glassy silica (SiO2) layer on the substrate surface.

Molybdenum metal-based alloy TZM (Mo–0.5Ti–0.1Zr–0.02C) is a potential material for high temperature applications such as nuclear reactor, hypersonic vehicle, space etc, as it offers high strength and creep properties at higher temperatures (~1500ºC). Mo in the TZM alloy forms volatile oxide vapor MoO3 at higher temperatures (beyond 700˚C) in oxidizing environments, which leads to damage of components during application. Development of a suitable protective coating is necessary for its use at high temperatures. This technology demonstrates the formation of silicide-based coating on TZM material using pack cementation technique.

Pack siliconizing technique produces uniform and adherent coating of desired thicknesses on larger components, as well as complex geometries. The different process steps can be conducted using minimum manpower.

Formation of protective coating is necessary to improve the high temperature oxidation resistance of the TZM alloy. Silicide-based coating (MoSi2) on TZM alloy shapes is promising material against oxidation at temperatures beyond 1200º due to the formation a protective, glassy silica (SiO2) layer on the substrate surface.

Preparation of anti oxidation coating on TZM alloy shapes is achieved by pack siliconizing process.

RAW MATERIALS

The raw materials for Pack siliconizing consisted of silicon metal (Si) powder, halide-based activators (NH4F), and alumina (Al2O3) as filler materials.

INFRASTRUCTURE

For the preparation of anti oxidation coating on tzm alloy shapes, equipments comprise of a controlled atmosphere resistance heating furnace, laboratory ovens, micro balance and tumbler mixer.

MANPOWER

The manpower requirements depend on the capacity and the extent of automation. 1 Metallurgist, & 2 skilled lab technicians are required to start the production.