Core Research & Development areas include

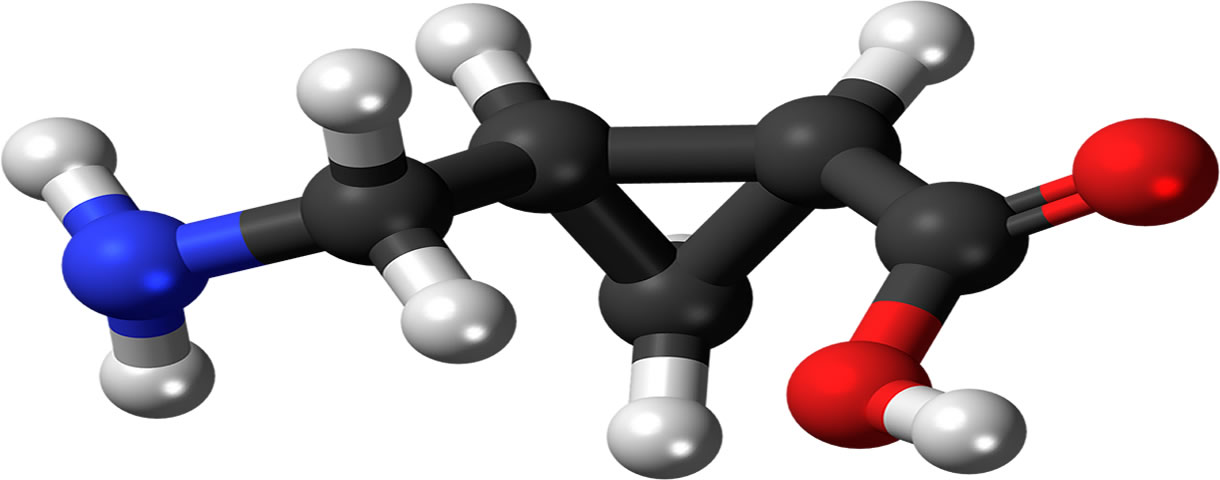

Research and Development in the area of Chemical Engineering is in line with the Departmental mandate related to Energy, National Security, Water security and Environment. Special focus is on development of process and technologies for separation, purification and production of materials required in the nuclear fuel cycle. State of art tools like atomistic and continuum modeling and simulation, process intensification, development of novel and green chemicals and waste minimization are utilized in all process developments to make it environment friendly and also cost competitive.

The key features underlying the development effort are self-reliance, achieving products with very high purity specifications, working with separation processes characterized by low separation factors, aiming high recoveries, optimal utilization of scarce resources, environmental benignity, high energy efficiency and stable continuous operation. CFD modeling, process simulation, development of novel contactors, highly specific extractants, catalysts and membranes are being used as tools for process and equipment development and intensification. Non-power application of nuclear energy has been demonstrated in the area of water desalination using the technologies such as Multi Stage Flash Distillation and Multi Effect Distillation with Thermo Vapor Compression (MED-TVC). Membrane technologies have been deployed not only for nuclear waste treatment but for society at large in line with the Jal Jeevan Mission of Government of India to provide safe drinking water at the household level.

Recent and ongoing research and development activities include: development and demonstration of fluidized bed technology for applications in nuclear fuel cycle;synthesis and evaluation of novel extractants; synthesis of TBM materials (synthesis of lithium titanate pebbles); molecular modeling for various phenomena (such as permeation of hydrogen and its isotopes through different metals, desalination using carbon nanotubes, effect of composition of glass on properties relevant for vitrification, design of solvents and metal organic frameworks);applications of microreactors for intensification of specific processes; development of low temperature freeze desalination process; environment-friendly integrated zero liquid discharge based desalination systems; treatment of industrial effluents; new generation membranes (such as high performance graphene-based nanocomposite membranes, membranes for haemodialysis, forward osmosis andmetallic membranes); hydrogen generation and storage by various processes (electrochemical water splitting, iodine-sulphur thermochemical, copper-chlorinehybrid thermochemical cycles); development of adsorptive gel materials for specific separations; heavy water upgradation; metal coatings for various applications (such as membrane permeator, neutron generator andspecial applications);fluidized bed chemical vapour deposition; andchemical process applications of Ultrasound Technology (UT).

Under R&D on cryogenics, a pre-cooled modified Claude cycle based 50 l/hr capacity helium liquefier (LHP50) has been developed and commissioned by BARC at Trombay. Major component technologies involved in LHP50 include ultra-high speed gas bearing supported miniature turboexpanders and compact plate fin heat exchangers along with cryogenic piping and long-stem valves all housed inside the LHP50 Cold Box. Other major equipment include a coaxial helium transfer line and a liquid helium receiver vessel