Tackling radioactive wastes efficiently

Any activity related to the nuclear fuel cycle, that produces or uses radioactive materials generates radio-active waste. The management of radiation emitting radioactive material is a matter of concern and is what sets nuclear wastes apart. Public acceptance of nuclear energy largely depends on the public assurance for safe management of radioactive wastes. Not all nuclear wastes are particularly hazardous or difficult to manage as compared to other toxic industrial wastes.

Safe management of radioactive waste has been accorded high priority right from the inception of our nuclear energy program. In accordance with international guidelines, a coherent comprehensive and consistent set of principles and standards are being practiced all over the world for waste management system. Radioactive waste would be managed in a manner so as not to cause any undue radiation risk to the workers, the public (present as well as future generation) and the environment.

Management of these wastes covers the entire range of activities right from handling, treatment, conditioning, transport, storage and disposal. The recent technological developments in India realize the recovery of valuable radionuclide from radioactive waste for societal application besides ensuring the highest level of safety in the management of radioactive waste.

Understanding radioactive wastes

Radioactive wastes are generated during various operations of the nuclear fuel cycle as well as production and use of radionuclide for various societal applications. The activities like mining and processing of uranium ore, fabrication of nuclear fuel, generation of power in nuclear reactor, processing of spent nuclear fuel, management of radioactive waste, production and use of radionuclide for various industrial and medical applications, research associating with radioactive material etc. generates the different types of radioactive waste. Radioactive waste can be in gas, liquid or solid form, and its level of radioactivity can vary. The waste can remain radioactive for a few hours or several months or even hundreds of thousands of years. Depending on the level and nature of radioactivity, radioactive wastes can be classified as exempt waste, Low & Intermediate level waste and High Level Waste. The most important and advantageous property of radioactive waste is 'Its radioactive hazard potential reduces with time depending on the half lives of radionuclide present in the waste'. Such feature differentiates them significantly from conventional chemical or industrial waste, hazard potential or toxicity of which does not alter with time and remains constant till its transformation to other suitable form.

Low and Intermediate Level Waste (LILW)

Low and Intermediate Level Waste (LILW) radioactive waste are generated in radiation facilities and nuclear fuel cycle operations ranging from uranium processing, fuel fabrication, nuclear power plants, research reactors, radiochemical facilities and fuel reprocessing. LILW have generally high volumes and low levels of radioactivity. They are segregated based on their physical nature and different management techniques have been established based on their nature for their effective treatment. They are further classified based on their radioactivity as well as also based on half life of radionuclide, as short lived and long lived wastes. Significant quantum of LILW of diverse nature gets generated in different nuclear installations.

They are essentially of two types

Primary Wastes comprising of radioactively contaminated equipment (metallic hardware) spent radiation sources etc.

Secondary wastes resulting from different operational activities, protective rubber and plastic wears, cellulosic and fibrous material, organic ion exchange resins filter cartridges and others.

High Level Waste

High level radioactive liquid waste (HLW) containing most (~99%) of the radioactivity in the entire fuel cycle is produced during reprocessing of spent fuel. A major stream of this waste is the aqueous radioactive waste generated from the first cycle extraction of the spent fuel processing. Also solid waste not suitable for disposal in near surface disposal facilities due to significant concentration of long-lived radionuclides or decay heat above the prescribed limits may also need to be regarded as high level waste. Issue of the long lived radioactive waste has been the focal point of debate for the success of nuclear power. Planning for management of HLW thus takes into account the need for their effective isolation from the biosphere and their continuous surveillance for extended periods of time spanning several generations. To meet this objective in the long term, waste isolation systems comprising multiple barriers are employed so as to prevent the movement of radionuclides back to the human environment.Management of radioactive wastes

Utmost emphasis is given to waste minimization, and volume reduction in the choice of processes and technologies adopted in radioactive waste management plants. As a waste management philosophy, no waste in any physical form is released / disposed to the environment unless the same is cleared, exempted or excluded from regulations. A comprehensive radioactive waste management is established taking into account the operational capability for the management of radioactive waste and an independent regulatory capability for its overview.

In consideration to the primary objective of protecting human health, environment and future generations, the overall philosophy for safe management of radioactive wastes in India, is based on the concept of

Effective management involves segregation, characterization, handling, treatment, conditioning and monitoring prior to final disposal.

Solid Waste

Substantial amount of LIL wastes of diverse nature, gets generated in different nuclear installations as radioactive solid waste. Treatment and conditioning of solid wastes are practiced, to reduce the waste volume in ways, compatible to minimizing the mobility of the contained radioactive materials. A wide range of treatment and conditioning processes are available today with mature industrial operations involving several interrelated steps and diverse technologies.

Proper disposal of Solid waste is essential to ensure protection of the health and safety of the public and quality of the environment including air, soil, and water supplies. Radiological hazards associated with short lived wastes < 30 years half life get significantly reduced over a few hundred years by radioactive decay. Disposal of waste is carried out in specially constructed engineering modules such as stone lined trenches, reinforced concrete trenches and tile holes at Near Surface Disposal Facility (NSDF). These disposal structure are located both above and under-ground in access - controlled areas and are designed based on multi barrier principle for ensuring effective containment and isolation of the radioactivity till it decays to innocuous level. The NSDFs where the disposal structures are located are kept under constant surveillance with the help of bore-wells laid out in a planned manner by routinely monitoring the underground soil and water samples to confirm effective confinement of radioactivity present in the disposed waste.

The high level solid wastes contain large concentration of both short and long lived radionuclide's, warranting high degree of isolation from the biosphere and usually calls for final disposal into Geological Disposal Facility (GDF). A key idea was that long-term disposal would be best carried out by identifying suitable sites at which the waste could be buried, a process called deep geological disposal.

Liquid Waste (LIL)

Liquid waste streams are pre-treated by various techniques, such as filtration, adsorption, chemical treatment, evaporation, ion exchange; reverse osmosis etc., prior to immobilization in suitable matrix depending upon the nature, volume & radioactivity content.

Gaseous Waste

Gaseous waste is treated at the source of generation. Various techniques involoving adsorption on activated charcoal, absorption / scrubbing, filtration by high efficiency particulate air filter etc., are used for effective treatment of gaseous waste

Management of High Level Waste

High level radioactive waste gets generated during reprocessing of spent fuel. Most of the radioactive isotopes in high level waste emit large amounts of radiation and have long half-lives. The management of high level waste in the Indian context, is carried out in the following three stages:

Vitrification

India is one of the few countries to have mastered the technology of vitrification. Over the years BARC has developed the technology for vitrification of HLW. India has a unique distinction of having operating vitrification plant at Trombay, Tarapur and Kalpakkam.

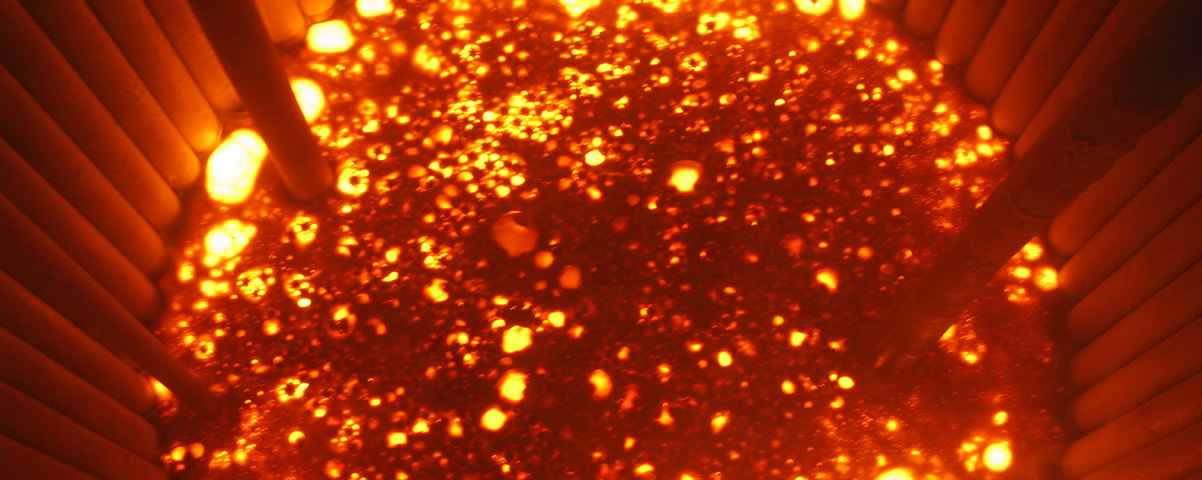

In our existing plant at Trombay vitrification process is essentially batch operation consisting of heating and fusing of pre-concentrated waste and glass forming additives and is carried out in Induction Heated Metallic Melter based on induction heating.

While the plant at Trombay is based on pot glass technology, the concept of Joule Heated Ceramic Melter (JHCM) is utilized at the facility at Tarapur. The Joule Melter Technology is essentially a single step process, where immobilisation of HLW in a borosilicate glass matrix is achieved in a refractory-lined melter. The Joule Heated Ceramic Melter (JHCM) process exploits the high temperature behaviour of glass whereby it becomes an electrical conductor at elevated temperatures and favourable changes in its viscosity near the pour point, helps in product withdrawal and shut off. The distinctive features of the Advanced Vitrification System (AVS) of Tarapur and Waste Immobilisation Plant, Kalpakkam, employing JHCM for vitrification of HLW, are increased throughput, availability of higher furnace temperature and minimum dependence on operator skills.

Cold Crucible Induction Melter (CCIM) is emerging as a futuristic technology for vitrification of high level liquid waste. Besides being compact and advantageous as in-cell equipment, it offers flexibility, susceptibility to treat various waste forms with better waste loading and enhanced melter life. The CCIM is manufactured from contiguous segments forming a cylindrical volume, but separated by a thin layer of electrically insulating material. The number and the shape of the segments and the insulating gap between them must be optimized to minimize the power dissipation by induced currents in the crucible, while ensuring cooling of the crucible.

Interim Storage of Vitrified Waste

The vitrified product is encapsulated in suitable containers and over packs and stored for dissipation of radioactive decay, heat and surveillance for a period of 15-20 years. Sufficient data can be generated on the product behavior and the radiation and thermal conditions of the product are expected to get stabilized to a level where transport of the product becomes viable. On the basis if safety and techno-economic considerations, a natural draught air cooling system has been designed for the storage vault.

Wealth from Waste

High level radioactive liquid waste contains various useful fission product such as 137Cs, 90Sr,106Ru etc., which have many industrial as well as medical applications. The energy associated with these isotopes can be used for blood irradiation, food preservation, sewage treatment, therapeutic applications, brachy therapy & various other industrial applications. Separation and recovery of these useful isotopes from radioactive waste and their deployment for societal application makes the waste as a material of resource.

137Cesium glass pencils for irradiation

137Cs can be used as a prominent alternate irradiation source to 60C° for various applications like blood irradiator, food irradiator, irradiation of sewage sludge etc. Due to longer half-life of 137Cs as compare to 60Co, the radiation sources need to be replaced at lesser frequency. 137Cs is available in large quantity in radioactive waste as one of the principal fission product. In-house development of selective extractants and their deployment has resulted into recovery of bulk of 137Cesium from waste. The recovered 137Cs solution is converted into non- dispersible cesium glass pencil to be used as blood irradiator. Few lac Ci of 137Cs have been recovered successfully and are converted into Cs glass pencils each having activity of 2.0 to 5.0 Ci/gm of 137Cs at Waste Immobilization Plant Trombay. These pencils have been supplied to various hospitals through BRIT after ensuring rigorous quality assurance. Research and Development is being pursued to make use of Cs glass pencils for other irradiation process such as food irradiation.

90Stronium for milking of 90Yttrium for radiopharmaceutical application

90Sr, another isotope present in waste, decays to 90Y by beta decay having its application as a radiopharmaceutical product for therapeutic use during treatment of cancer. In-house developed strontium selective extractant has been successfully deployed for separation/ recovery of strontium from HLW and converting into Yttrium generator. 90Y is milked out from purified 90Sr using in-house developed membrane technology and supplied for radiopharmaceutical application.

106Ru for eye cancer treatment

106Ru has an important application for eye cancer treatment as a brachy therapy. Till date, 106Ru plaques are imported. Technology for recovery of 106Ru from nuclear waste and fabrication of 106Ru containing silver plaque has been successfully developed as an import substitute for eye cancer treatment along with cost effectiveness. Ru plaques, containing about 300-600 microcurrie of Ru-106 activity, are produced and supplied to various eye hospitals through BRIT for eye cancer treatment. The indigenously developed Ru-106 eye plaques are cost effective and thier performance is at par the international standard.

Summary

Safe management of radioactive waste has been accorded high priority right from the inception of our nuclear energy program. As a result of rugged design with 'defense in depth' concept, well established practices and safety review by independent agency, an excellent track record for safe management of radioactive waste in India has been demonstrated for more than five decades. Consistent efforts in R&D has enabled indigenous development of novel processes and technologies in the field of management of radioactive waste and their deployment to realise the waste volume minimization, effective isolation of radionuclide in engineered matrix, minimization of discharges and extracting wealth from waste by separating useful radionuclide from radioactive waste for societal applications. Such developments enable the country to be front-runner in the field of radioactive waste management in the world.