After certain energy utilization, known as burn-up (a legacy of thermal power) is reached, nuclear fuel in a reactor is replaced by fresh fuel so that fission chain reactions can sustain and desired power output can be maintained. The spent fuel discharged from the reactor is known as Spent Nuclear Fuel (SNF). Most countries consider SNF a waste, necessitating suitable disposal. Such a once-use programme is termed an open fuel cycle. In fact, over 95-99 % of the original fuel material remains in the SNF and recovery of Pu and U (Special Nuclear Materials – SNMs) from spent fuel allows their use in next generation reactors as mixed oxide (MOX) fuels. In a closed fuel cycle, such as that adopted in India, spent fuel is recycled for extraction of useful materials such as U and Pu as mentioned previously. A key component to any closed fuel cycle programme is reprocessing, and this is also a crucial step in the Indian three stage nuclear fuel programme, which envisages the long-term use of abundant Thorium reserves. Indeed, the closed cycle not only helps in optimal utilisation of resources but also permits recovery of valuable radionuclide, followed by significant reduction of waste volume as compared to an open cycle.

REPROCESSING OF SNF

BARC has come a long way since it first began reprocessing of spent fuel in the year 1964 at Trombay. India has more than five decades of experience for reprocessing of spent fuel of Uranium based first stage reactor resulting in development of well matured and highly evolved PUREX based reprocessing flow sheet involving recovery of SNM. Multidisciplinary R&D is aimed to get product stream of desired quality with better separation factor aiming to improved decontamination factor for fission product and reduced waste volume. As a result of structured and focused R&D in the field of reprocessing of SNF, reprocessing plants at Tarapur and Kalpakkam sites of India are under successful operations to reprocess the SNF generated from the Pressurised Heavy Water Reactors (PHWRs) enabling recovery of SNM for next generation reactor (PFBR). Still, scope do exists for further improvisation of technology pertaining to head end systems as well as separation systems for reducing the personnel exposure, improving reprocessing capacity and separation of various radionuclide for effective management of waste. In view of rapid expansion of nuclear power programme to meet the projected demand of electricity, larger through put reprocessing plants like Integrated Nuclear Recycle Plant (INRP) are strongly needed realising the concept of "SOLID IN & SOLID OUT" with a plant design capacity of 600 Tones of Heavy Metal per annum. This calls for development and scaling up of separation equipments to enhance the capacity by multifold.

Implementation of Thorium fuel cycle requires extraction of 233U from irradiated thorium fuel and its re-insertion into the fuel cycle. Based on indigenous efforts, a flow sheet for reprocessing of spent thoria rods was developed and demonstrated at Uranium Thorium Separation Facility (UTSF), Trombay. After gaining successful experience at UTSF, Power Reactor Thoria Reprocessing Facility (PRTRF) has been set up employing advanced laser based technology for dismantling of thoria bundle and single pin mechanical chopper for cutting of fuel pins. Thoria irradiated fuel bundles from PHWR were reprocessed using TBP as extractant to recover 233U.

MANAGEMENT OF NUCLEAR WASTE:

Wastes while small in volume, are generated from nuclear reactor operation; or any other industrial activity utilizing radioactive materials, necessitates suitable management. During the reprocessing operations, various secondary streams are generated, some of them being product and many of the streams as wastes. Safe management of nuclear waste has been accorded high priority right from the inception of nuclear energy programme of India to ensure safety and protection of environment, human health and future generation. The prevalent philosophy has been toward isolation of nuclear wastes after suitable conditioning in an inert matrix to mitigate dispersal concerns. Of late, there has also been an increased appreciation that nuclear waste can be a valuable resource for the extraction of various radionuclides which can be useful in valuable societal applications. This has led to the concept of viewing nuclear waste as wealth, a view vindicated by the development of selective extractants, advanced separation techniques, remote handling equipments to ascertain recovery of valuable radionuclide like 137Cesium, 90Stronium, 106Ruthenium.

Nuclear waste in the form of gaseous, liquid and solid is generated during operation & maintenance activities of nuclear fuel cycle facilities. Gaseous waste is treated at the source of generation using the techniques such as absorption-chemical scrubbing, adsorption on activated charcoal and filtration by high efficiency particulate air filter. Liquid waste streams are treated by various techniques, such as filtration, adsorption, chemical treatment, evaporation, ion exchange; reverse osmosis etc. depending upon the nature, volume & radioactivity content. Further research is focussed to develop the technology for attaining the objective of 'Near Zero Discharge' of radioactivity to the environment. The radioactive solid wastes generated are segregated and volume reduced prior to its disposal in specially constructed engineered disposal structures such as stone lined trenches, reinforced concrete trenches and tile holes for ensuring effective containment of the radioactivity till the radionuclide decays innocuous level. Recent developments are focussed towards waste volume minimisation by incorporating new technologies including high pressure compaction, plasma based incineration system etc. Efforts are also being put towards development of disposal modules with effective containment and space utilisation.

High Level Liquid Waste (HLLW) generated during reprocessing of spent fuel contains most of the radioactivity generated in entire nuclear fuel cycle. The HLLW is immobilised into an inert Sodium Boro-Silicate glass matrix through a process, called vitrification. The vitrified waste is stored for an interim period in a air cooled vault to facilitate the dissipation of heat generated during decay of radioactivity. prior to its eventual disposal in geological disposal facility. Vitrification of HLLW is a complex process and poses challenges in view of high temperature operations in presence of high amount of radioactivity. As a result very few countries in world could master the technology of vitrification of HLLW and India is among them. Three melter technologies, Induction Heated Metallic Melter (IHMM), Joule Heated Ceramic Melter (JHCM) and Cold Crucible Induction Melter (CCIM), have been indigenously developed for vitrification of HLLW. HLLW vitrification plants, based on IHMM or JHCM technologies, have been constructed and successfully operated at Trombay, Tarapur and Kalpakkam sites of India.

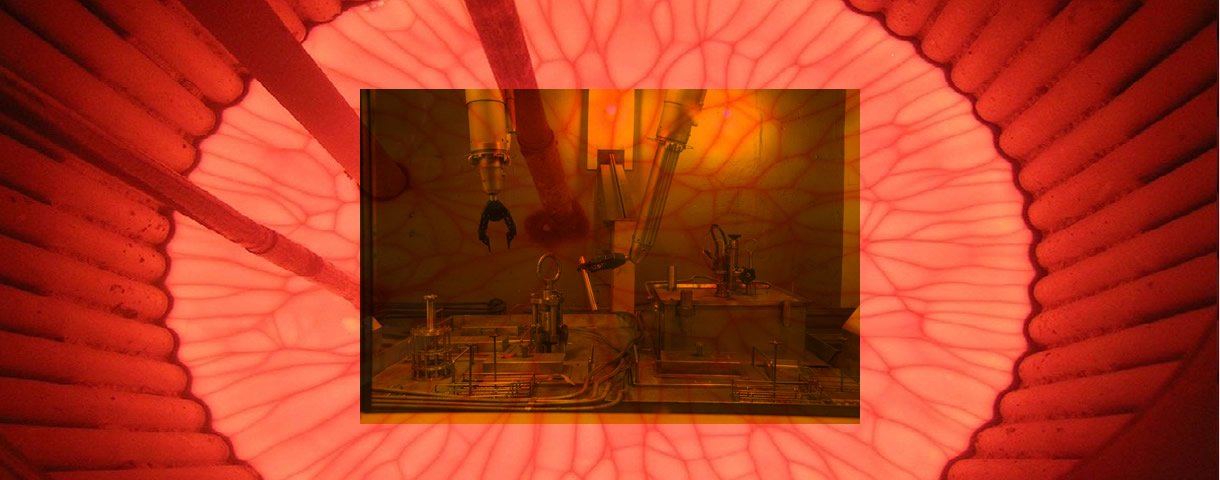

Vitrification Cell (IHMM), WIP, Trombay Joule Heated Ceramic Melter, Tarapur Inside view of Cold Crucible Induction Melter R&D in the field of partitioning of Minor Actinides from HLLW are also aimed to separate out the long - lived radioactive waste constituents prior to immobilizing then in glass matrice. The long lived radio-contaminants is planned to be burnt in fast reactors or Accelerator Driven Sub Critical systems to get converted into short- lived species. This will reduce the need of long term isolation of radionuclide from environment by multifold. R&D is also directed towards management of Hulls, contaminated left over pieces of zirconium clad tube after dissolution of fuel, and Geological Disposal Facility for safe disposal of vitrified HLLW and long lived waste with objective to long term isolation of radionuclide from the human environment.

VALUE RECOVERY FROM NUCLEAR WASTE

With advent of development of new technology, India has taken a lead role in separation of useful radio-isotopes present in HLLW having various medical as well as industrial applications. Radioisotopes like 137Cs, 90Sr, 106Ru have many industrial as well as medical applications. The energy associated with these isotopes is used for blood irradiation, food preservation, and therapeutic applications. Separation and recovery of useful isotopes from radioactive waste and their deployment for societal application makes the waste as a material of resource. In-house development of selective extractants and their deployment has resulted into recovery of bulk of 137Cesium & 90Strontium from waste. The 137Cs solution is recovered and converted into non- dispersible cesium glass pencil and supplied to various hospitals for use in blood irradiator.

CESIUM RECOVERY AND CESIUM GLASS PENCIL MAKING SYSTEM, WIP, TROMBAY

90Strontium, another isotope present in waste, decays to 90Yttrium by beta decay having its application as a radiopharmaceutical product for therapeutic use during treatment of cancer. The use of in-house recovered 90Yttrium, as import substitute, helps in serving common people more cost effectively. In-house developed multi step separation techniques are deployed for selective separation of Strontium from HLW and converting into Yttrium generator. 90 Yttrium is supplied to RMC, Parel for radiopharmaceutical applications.

106Ruthenium is also available in HLLW and has potential application for treatment of eye cancer. Based on indigenous R&D efforts, recovery of 106Ruthenium (in purified form) from waste followed by electrodeposition of 106 Ruthenium on silver plaque for making Ru-106 eye plaques have been successfully demonstrated. The indigenously developed Ru-106 eye plaques, as an import substitute, are being supplied to various hospitals for cost effective treatment of eye cancer.

Thus, with the advent of indigenously generated innovative solvents and incorporation of selective separation processes, Indian nuclear waste management program has taken a new philosophy towards adoption of separation and recovery of fission products and deploy them for societal benefits thereby extracting potential wealth valuables from the radioactive wastes.