MATERIALS GROUP

MATERIALS PROCESSING DIVISION

Dr. ALOK AWASTHI

Head of Division

- :

+91 22 25590481

- : webmaster@barc.gov.in

- : www.barc.gov.in

- :

Materials Processing & Corrosion Engineering Division

2-319-S Modular Laboratory

Bhabha Atomic Research Centre

Mumbai

Maharashtra 400085

India

Mandate

To develop and provide materials, process flow sheets and fabrication technologies to meet the emerging needs of evolving indigenous nuclear energy program by proactive research and development on a continuing basis.

Highlights

Technologies Developed

Show Cases

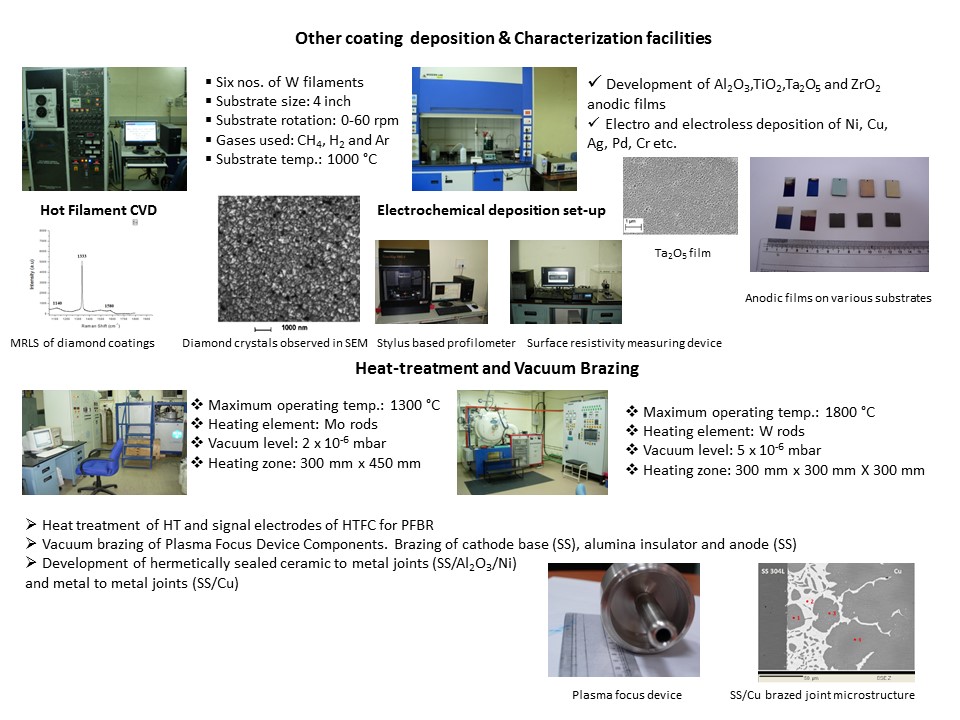

Heat-treatment and Vacuum Brazing